"An ion-exchange resin or ion-exchange polymer is a world class resin or polymer available in uniform size beads and in dry and moist form. In many cases ion-exchange resins were introduced in processes as a more flexible alternative to the use of natural or artificial zeolites. This product line has been well-known for its versatility and reliability for many years now, which is why we are proud to offer them for industries such as sugar mill, pharma, bio-diesel, nuclear, food & beverage and many more."

The process chemical creates a wide impact over the pH level with maximum inhibition of fungi and bacteria which minimise sugar loss in the content and slime formation.

The Ion Exchange Manual Softener uses a process called ion exchange where the softener is placed in the water and changes some of the ions in the water, making it softer and more alkaline. This helps reduce chlorine taste and odor, which can be unpleasant if you're using well water or hard water from your local municipality. .

Ion exchange auto softeners are a type of automatic softener that uses a combination of ion exchange and oxidation to remove excess hardness from water. Ion exchange is a process that exchanges positively charged ions for negatively charged ions in water. Oxidation occurs when oxygen reacts with the negatively charged ions to form positively charged oxygen ions.

"Activated carbon filters are generally employed in the process of removing organic compounds and/or extracting free chlorine from water, thereby making the water suitable for discharge or use in manufacturing processes. Eliminating organics in potable water, such as humic and fulvic acid, prevents chlorine in the water from chemically reacting with the acids and forming trihalomethanes, a class of known carcinogens. Activated Carbon (AC) filtration, as with any water treatment method, is not capable of removing every possible type of contaminant. For example, sodium, microbes, fluoride, and nitrates cannot be removed with AC filtration. Water softening also cannot be achieved with AC filters. In addition, heavy metals, such as lead, can only be removed with a very specific kind of activated carbon water treatment, which is typically used only in residential point-of-use filters."

Ion exchange sand filters are the most common type of filter used in commercial water treatment. The sand is saturated with resin, which attracts and binds with ions. The resin that's present in the sand is called synthetic zeolite, and it has a number of advantages over natural zeolites. These include its ability to bind larger amounts of contaminants than natural zeolites, which allows for better filtering performance at lower cost (since you don't have to use as much material).

Since our company started its business, we are persistently in offering comprehensive range of superior quality Multigrade Sand Filter (Carbon Filter) to our diverse clients. All these products are developed by skilled workforce to confirm international standard. The product is widely demanded for its high efficiency to filter sand from raw water. The offered products can be availed in customized range

Water softeners are a key part of any industrial plant's water treatment process. With the proper water softener, you can effectively remove minerals from your industrial water, which will help make it more suitable for your production processes. A water softener works by using a chemical process to remove minerals from the water, resulting in softened water that is less corrosive and more stable than regular tap water.

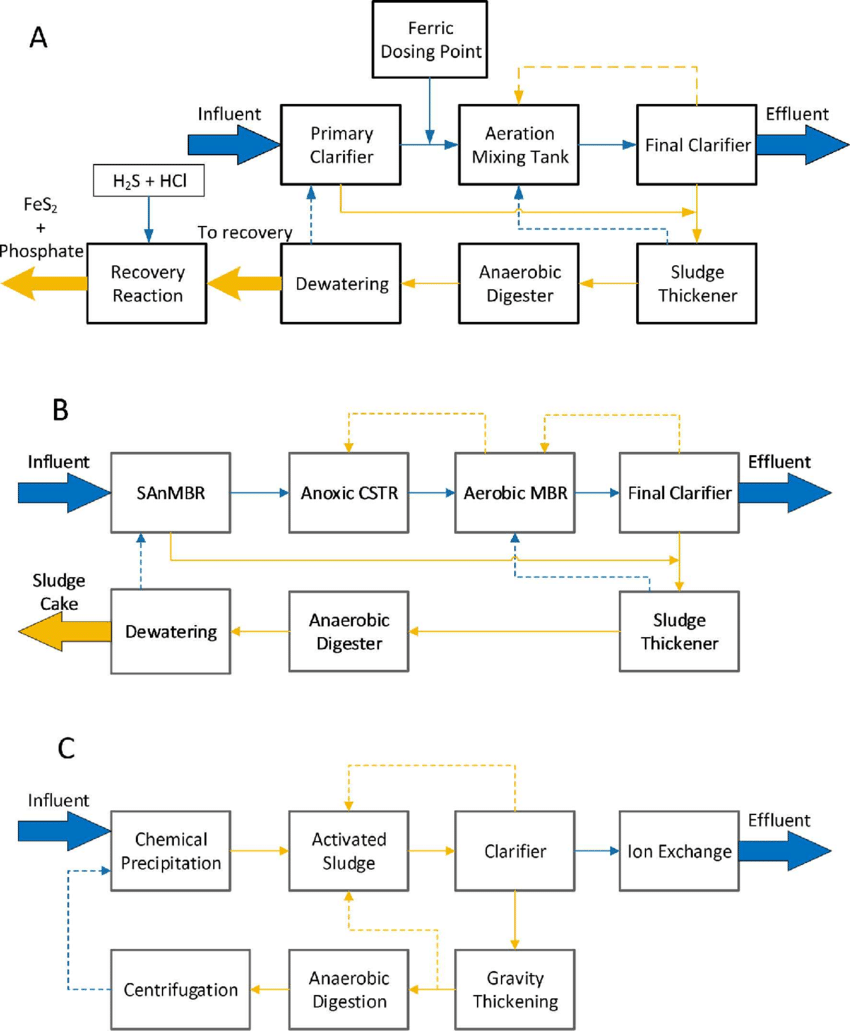

The ETP Plant is a new facility that treats industrial wastewater and storm water runoff by way of anaerobic digestion. The plant produces biogas, which can be used as a renewable energy source in the surrounding community. The treatment process uses physical filtration, chemical disinfection, and biological flocculation to remove pollutants from the water. It then stores the water until its capacity is reached, at which point it undergoes secondary treatment using anaerobic digestion to further purify it. Bhushan International has provided many ETP project solution from concept to design, commissioning, operation and maintenance of plant with the capacity of 20KLD and more.

"Sewage can be treated close to where it is created or collected and transported via a network of pipes and pump stations to a municipal treatment plant. The former system is gaining popularity for many new ECO towns, as 60% of the cost of mains sewerage is in the pipework to transport it to a central location and it is not sustainable. It is called 'Decentralisation' of sewage treatment systems. The job of designing and constructing sewage works falls to environmental engineers. They use a variety of engineered and natural systems to meet the required treatment level, using physical, chemical, biological, and sludge treatment methods. The result is cleaned sewage water and sludge, both of which should be suitable for discharge or reuse back into the environment. Sludge, however, is often inadvertently contaminated with many toxic organic and inorganic compounds and diseases and the debate is raging over the safety issues. Bhushan International has successfully executed and maintaing such plants for hospitals and goverment institutions. "